Most sticker decisions don’t fail because of design. They fail because the sticker format doesn’t match how the sticker is actually used.

At Overnight Prints, rectangle stickers are printed on sheets and kiss-cut, making them ideal for labeling, packaging, mailing, and professional applications where precision and ease matter more than novelty.

So when choosing between die-cut vs kiss-cut stickers, the real question isn’t which looks cooler, it’s which format fits the job.

This guide explains the difference clearly and shows why kiss-cut rectangle stickers are often the smartest choice for business use.

Die-cut vs kiss-cut: what’s the real difference?

Before we go deeper, here’s the clean distinction:

- Die-cut stickers

Cut completely through the sticker and backing. These are usually individual, loose stickers shaped exactly like the design. - Kiss-cut stickers

Cut through the sticker layer only, leaving the backing sheet intact. Stickers remain on a sheet and peel off easily.

Rectangle stickers at Overnight Prints are kiss-cut and printed on 8.5″ × 11″ sheets, which makes them more practical for professional and operational use.

| Feature | Die-Cut Stickers | Kiss-Cut Stickers |

| Cut style | Cut completely through sticker + backing | Cut through sticker only |

| Backing | None (single piece) | Full backing sheet remains |

| Ease of peeling | Moderate (can be tricky for small designs) | Very easy |

| Best for | Handouts, giveaways, bold branding | Packaging, mailers, inserts |

| Customer behavior | Applied immediately | Often saved for later |

| Design flexibility | Strong for bold shapes | Better for detailed designs |

| Storage & shipping | Loose, individual pieces | Flat, protected sheets |

| Perceived experience | Finished, gift-like | Practical, convenient |

| Common use cases | Events, trade shows, counters | Orders, boxes, envelopes |

Why rectangle stickers are printed on sheets (and why that’s a good thing)

For business use, function beats novelty.

Kiss-cut rectangle stickers printed on sheets offer several advantages:

- Easier handling during labeling and packing

- Faster application for bulk use

- Cleaner storage and shipping

- Less waste or damage

- Better alignment for text-heavy designs

That’s why rectangle stickers are commonly used for:

- Product packaging

- Mailing labels

- Corporate correspondence

- Retail labeling

- Office and manufacturing environments

Loose die-cut stickers simply don’t perform as well in these scenarios.

When kiss-cut rectangle stickers are the best choice

Kiss-cut stickers are ideal when stickers need to be used efficiently, not admired individually.

Rectangle stickers work best when:

- Stickers are applied in batches

- Designs include text or fine details

- Consistent placement matters

- The sticker functions as a label, not a giveaway

Because they remain on a backing sheet, kiss-cut rectangle stickers are easier to peel cleanly, especially for smaller sizes like 2″ × 1″ or 3″ × 1″, which are common for packaging and mail.

View available rectangle sticker options here: Stickers

Choosing the right material for your rectangle stickers

Rectangle stickers at Overnight Prints are available in materials designed for different environments and use cases:

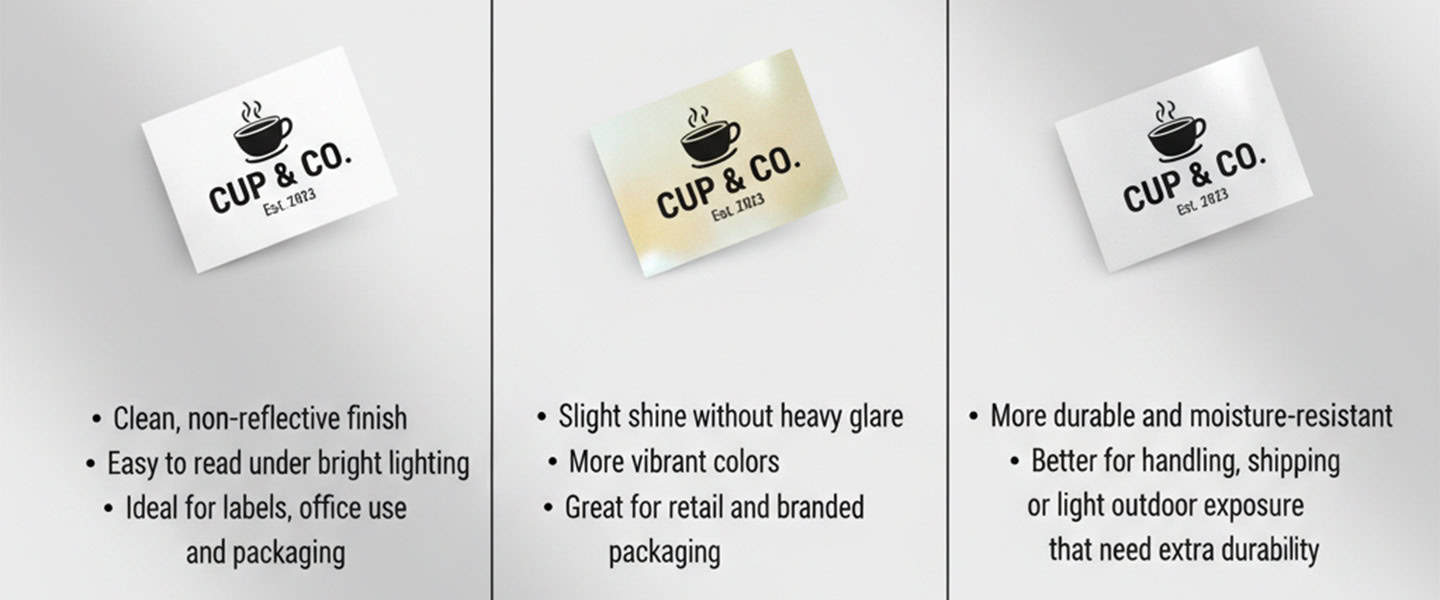

Matte Sticker (Adhesive)

- Clean, non-reflective finish

- Easy to read under bright lighting

- Ideal for labels, office use, and packaging

Semi-Gloss Sticker (Adhesive)

- Slight shine without heavy glare

- More vibrant colors

- Great for retail and branded packaging

2 Mil White Poly Sticker

- More durable and moisture-resistant

- Better for handling, shipping, or light outdoor exposure

- Ideal for products that need extra durability

Choosing the right material matters just as much as choosing the cut, especially when stickers are used repeatedly or handled often.

Common rectangle sticker sizes for business use

Rectangle stickers are available in multiple practical sizes, including:

- 2″ × 1″

- 3″ × 1″

- 3″ × 1.5″

- 3.5″ × 2.25″

- 3″ × 4″

- 4″ × 3.25″

- 4″ × 6″

Smaller sizes work best for:

- Mailing labels

- Product information

- Barcodes and branding marks

Larger sizes are better for:

- Retail signage

- Instructional labels

- Promotional packaging

5 Print Add-Ons That Boost Brand Loyalty (And Keep Customers Coming Back)

When die-cut stickers make more sense (and when they don’t)

Die-cut stickers work well when the sticker itself is the product, typically for giveaways, events, or decorative branding.

However, for rectangle stickers used in professional environments, die-cut formats can slow things down:

- Harder to peel in bulk

- Easier to misplace

- Less reliable for precise application

That’s why rectangle stickers are intentionally produced as kiss-cut sheets, they’re built for efficiency, not impulse use.

Final takeaway: choose the format that fits the job

Die-cut vs kiss-cut isn’t about better or worse, it’s about use case.

If you need:

- Speed

- Precision

- Clean application

- Professional consistency

Kiss-cut rectangle stickers on sheets are the right choice.

They’re designed to work, not just look good.

And when paired with the right material and size, rectangle stickers become one of the most versatile print tools a business can use.